Explore the offer

Growth & Synthesis / Chemical depositions of thin films

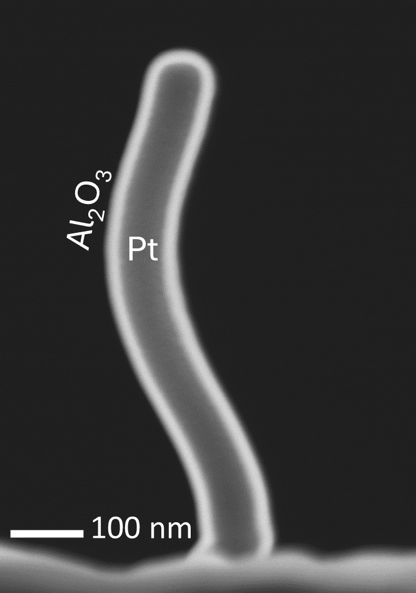

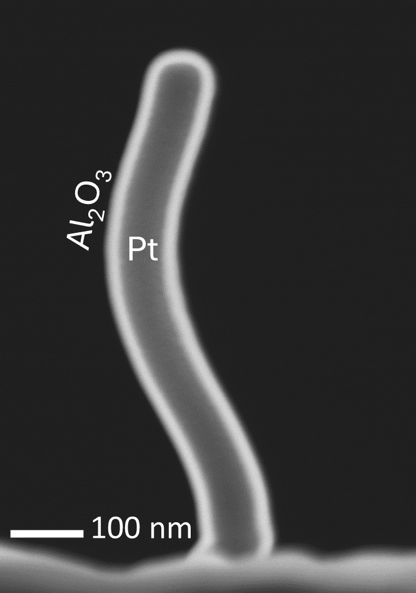

Atomic Layer Deposition

Atomic Layer Deposition (ALD) is similar to CVD except that the ALD reaction occurs at lower temperature and it is broken into two half-reactions, keeping the precursor materials separated during the reaction. The separation of the precursors is important to achieve a self-limiting surface reaction to enable precise thickness control and ensure uniform coatings and compactness even in complicated 3D structures.

The present implementation of the technique is suitable for mm to cm-size samples as those typically studied by spectroscopy and microscopy.

ALD has a rich history in microelectronics. It is studied as a potential technique to deposit high-k (high permittivity) gate oxides, high-k memory capacitor dielectrics, ferroelectrics, and metals and nitrides for electrodes and interconnects.

The number of materials that can be prepared by ALD has tremendously increased in the past decade. Notably, it can deposit a wider variety of materials, including important functional oxides like Al2O3, MoO3, SiO2 and HfO2.

Available instruments

Select instruments to view their specifications and compare them (3 max)

Lab's Facility

Lecce

CNR-NANOTEC@LE

Milano