Explore the offer

Lithography & Patterning / Patterning, replication, and sample navigation

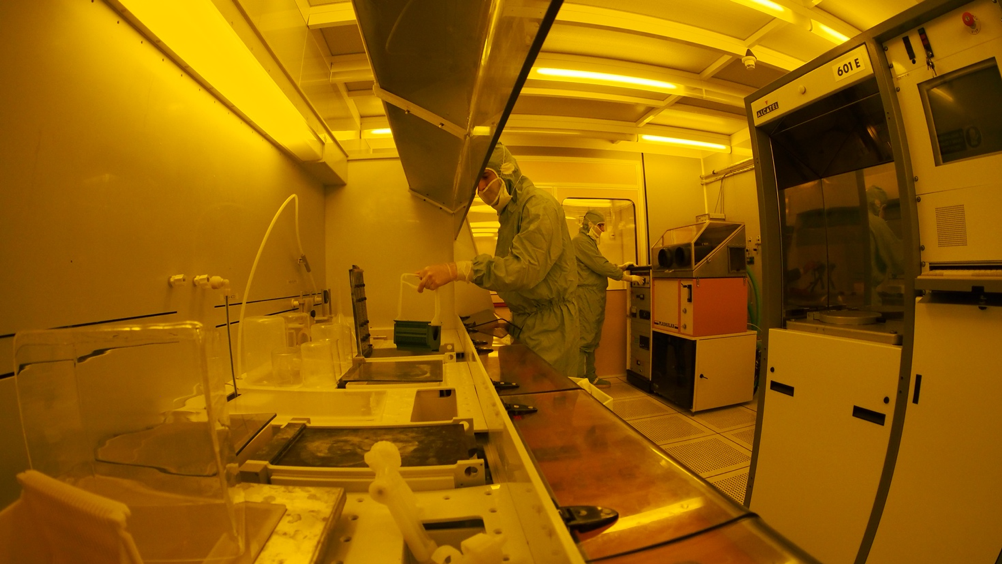

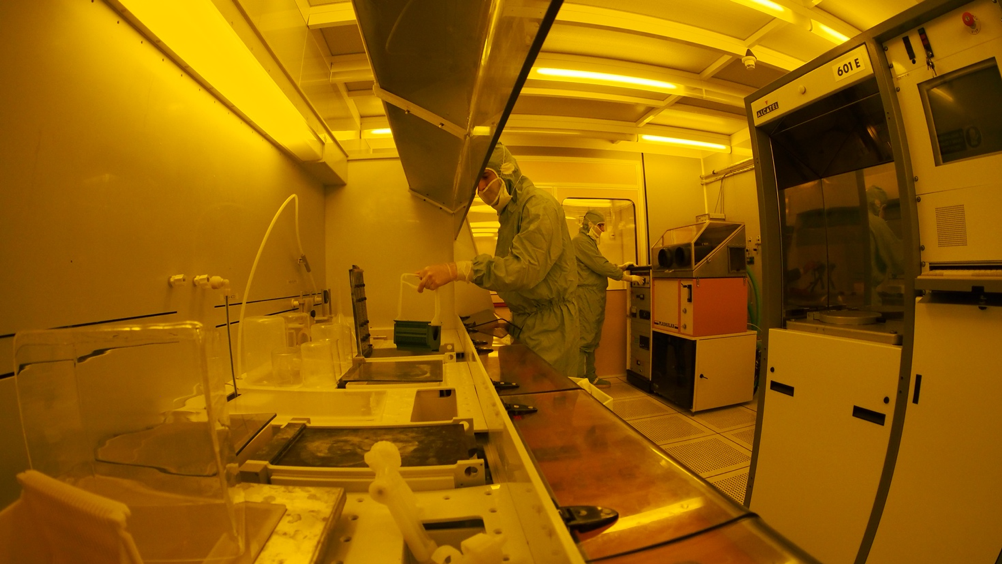

Wet Etching

The principle of wet etching processes is the conversion of a solid material into liquid compounds using chemical solutions. The selectivity is usually very high, and for most solutions is greater than 100:1. Material removal rate for wet etching is usually faster than the rates for many dry etching processes and can easily be changed by varying temperature and concentration of the active species. Multiple wafers can be etched simultaneously in batch etching; in this case filters and circulating pumps prevent particles from reaching the wafers.

When a material is attacked by a liquid or vapor etchant, it can be removed with isotropic (uniformly in all directions) or with anisotropic etching. In anisotropic etching the liquid etchants etch crystalline materials at different rates depending upon which crystal face is exposed to the etchant.

Wet or dry etching processes are common steps in the technological process flow for obtaining the material under study well patterned, isolated and ready to be contacted.

In particular, the process flow usually contains the required suite of pattern transfer and/or etching processes for ancillary materials, such as silicon nitride, silicon oxide, polysilicon that can be used as etching masks, implantation and diffusion barriers, dielectric barriers, spacers or conductive layers. Those materials can be etched and patterned by chemical wet etching or by Reactive Ion Etching (RIE) using appropriate masks or making use of lift-off process. Those materials can be used themselves as etching masks (for instance in the case of Al layers for deep RIE patterning of substrates), or as adhesion or barrier layers or directly as layers for providing the required electrical contact.

Available instruments

Select instruments to view their specifications and compare them (3 max)

Lab's Facility

Bologna