Explore the offer

Growth & Synthesis / Chemical depositions of thin films

Chemical Vapour Deposition

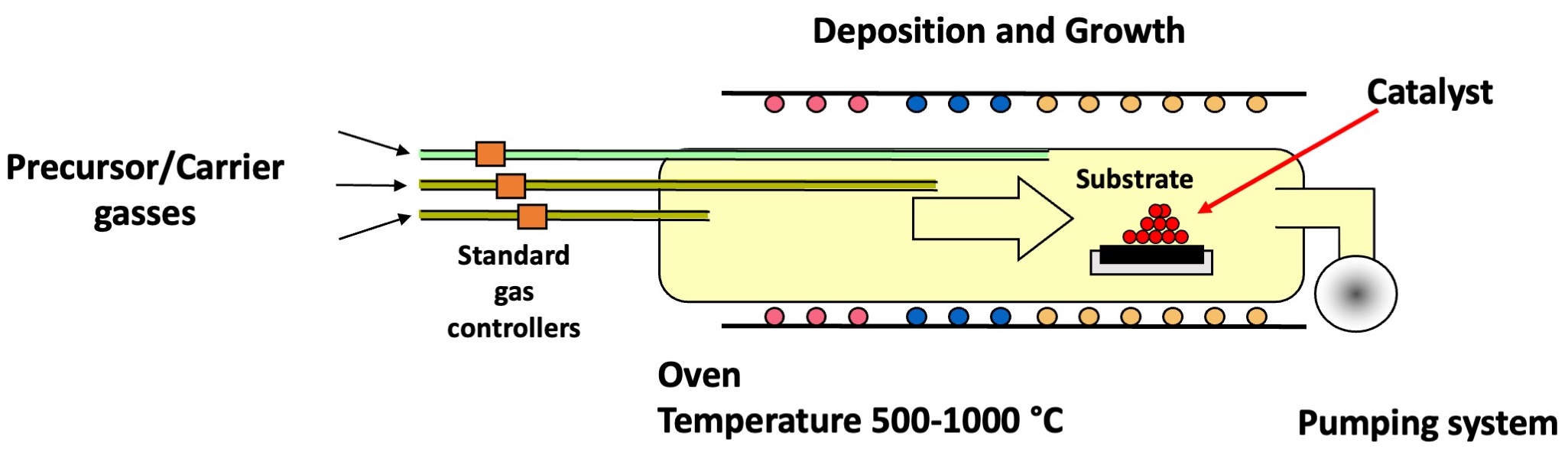

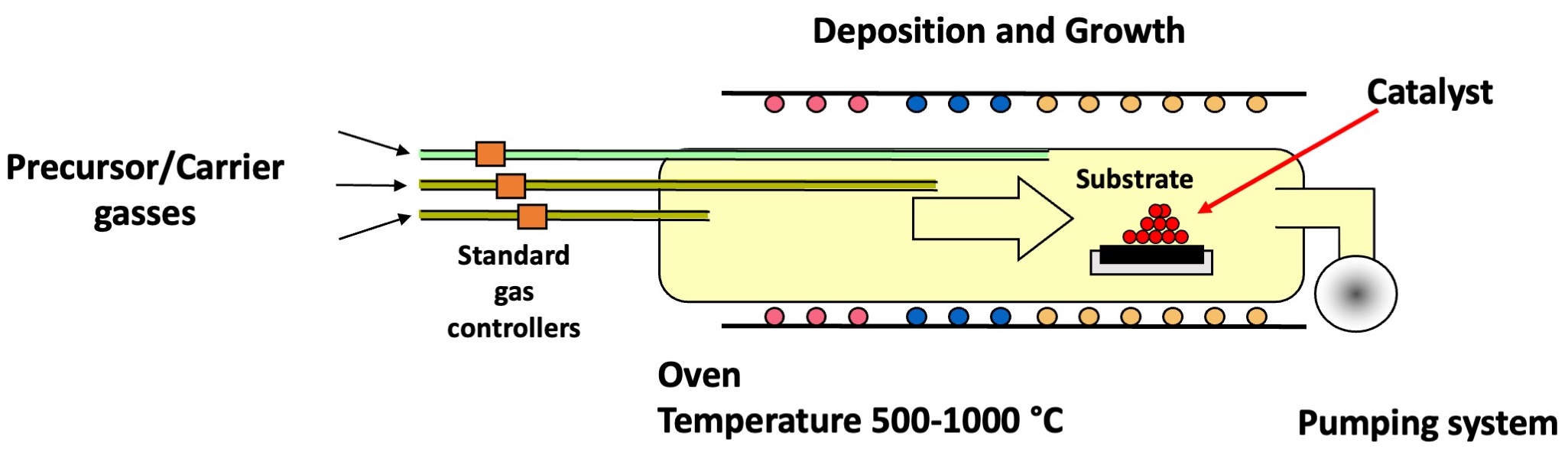

CVD is a thermal process because a certain thermal energy is needed to decompose the gas precursors and reassemble them in the material to be synthetize. Generally, in a CVD process, the substrate is maintained at high temperature while it is exposed to the volatile precursor/s, usually carried by an inert carrier gas (like Ar). High temperatures are usually required to decompose the precursors and to reassemble the products in the growing material.The use of a catalyst may allow to decrease the process temperature and to select the location and the nanostructure of the growning film. Together with the carrier and precursor gasses, other gasses, like etching gasses (like H2, NH3, …), may be used to avoid the formation of undesired species and to enhance the synthesis of the desired material. In high pressure CVD (atmospherics pressure) the use of an inert carrier gas helps to avoid gas-phase reactions (homogenous deposition) and favor the synthesis trough surface processes (heterogeneous deposition). When CVD is done at low pressure, the process is called Low Pressure CVD (LPCVD). In this case the reactions in the gas-phase of the precursors are reduced and the higher diffusivity of the precursor species favor to decorate cavities and led to get homogeneous coatings when a topography is present. The homogeneity is also spurred by the process temperature, which favors the mobility of the atomic/radical species along the surface. Process pressures are usually in the millitorr-torr range and process temperatures range is 400-800C (depending on the energy needed to decompose the precursors). To favor the precursor gas decomposition and to lower the CVD temperature, the CVD process may be assisted by a plasma, and in this case the technique is referred as plasma-enhanced CVD (PECVD). This usually allows lowering the temperature of the process to a few hundred centigrade degrees, which can be run on less temperature resistant substrates or without setting off temperature triggered unwanted processes.

The present implementation of the technique is suitable for mm to cm-size samples as those typically studied by spectroscopy and microscopy.

Available instruments

Select instruments to view their specifications and compare them (3 max)

Lab's Facility

Catania

CNR-IMM@CT

Bologna

CNR-ISMN@BO

Bologna

CNR-ISMN@BO

Bologna

CNR-ISMN@BO

Bologna

CNR-ISMN@BO

Bologna

CNR-ISMN@BO

Trento

CNR-IFN@TN

Catania