Explore the offer

Theory & Simulation / THEO & SIM

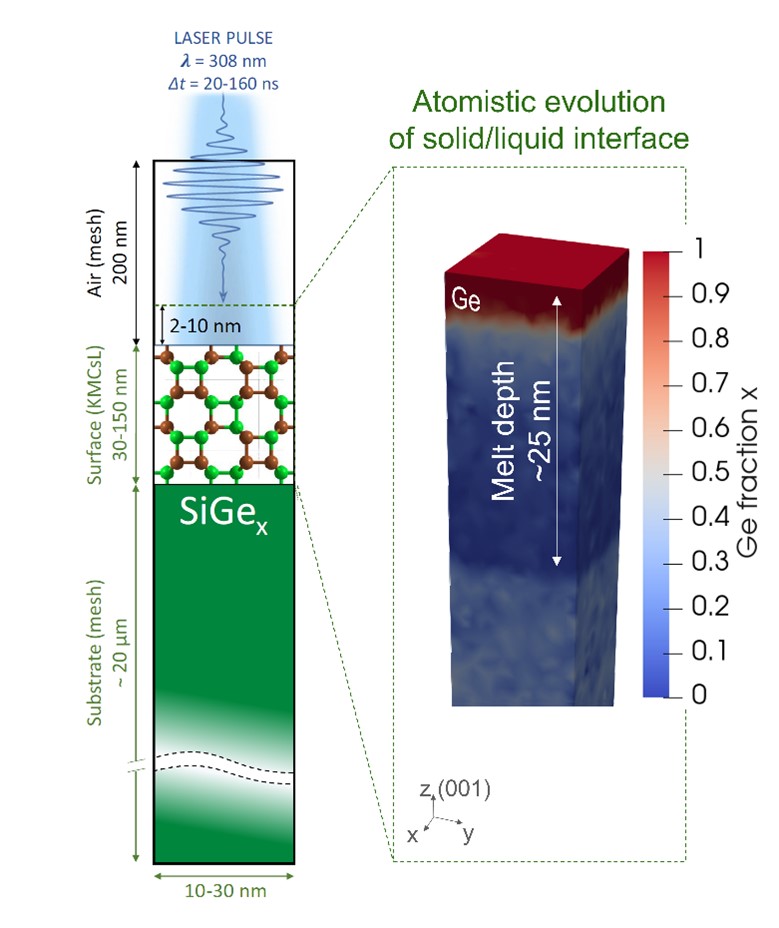

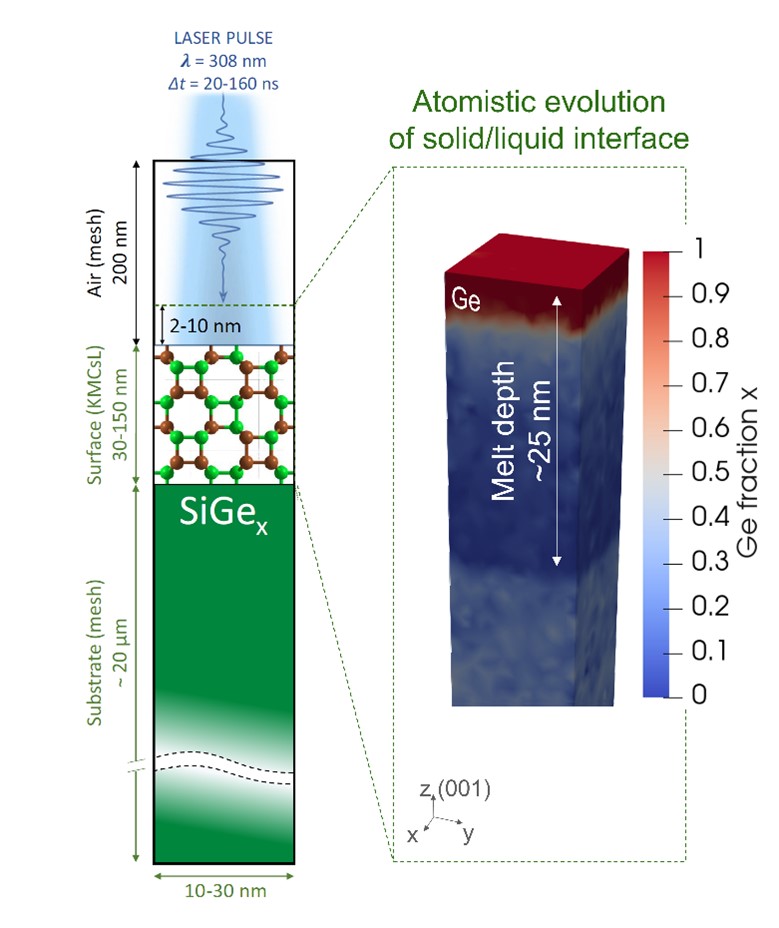

MULTI-SCALE PROCESS SIMULATION FROM THE MACRO TO THE ATOMIC SCALE

Material processing is the consequence of a complex evolution at the microscale driven by external controllable macroscopic fields and variables. Apart few exceptions the material processing occur over time scales that range from minutes to hours. The conventional process optimization procedure exploits the Design of Experiments (DoE or R-DoE Real-DoE) concept to assess with statistical techniques the impact of controllable variables’ variation on the microscopic material modification. This is costly approach which consist in several experiments (points of a multi-dimensional matrix of parameters) and for each experiment several, usually destructive, characterization analyses are performed to understand the process effects.

We offer simulation tools to assist material and (meso-nano) systems’ development by Virtual Design of Experiments (V-DoE) using multi-scale (from the equipment-scale to the nano-scale) simulations of processes.

Although some ultra-fast phenomenon can also be predicted by means of ab initio or semi-classical molecular dynamical (MD) methods, temporal extension of processes intrinsically limits the application of such accurate schemes for the simulation of the process evolution. In addition to ad-hoc MD studies, we offer also internally developed atomistic Kinetic Monte Carlo (KMC) and continuum approaches that overcome such limitations. Within a multiscale perspective, we can support the experimental development simulating the kinetic of manipulation processes proposed by the users for example: growth from the vapor phases, wet and dry etching, conventional and advanced (e.g. laser annealing) thermally activated processes, phase transformations etc.

Available instruments

Select instruments to view their specifications and compare them (3 max)

Lab's Facility

Catania